Metal Sandwich Panel

Introduction

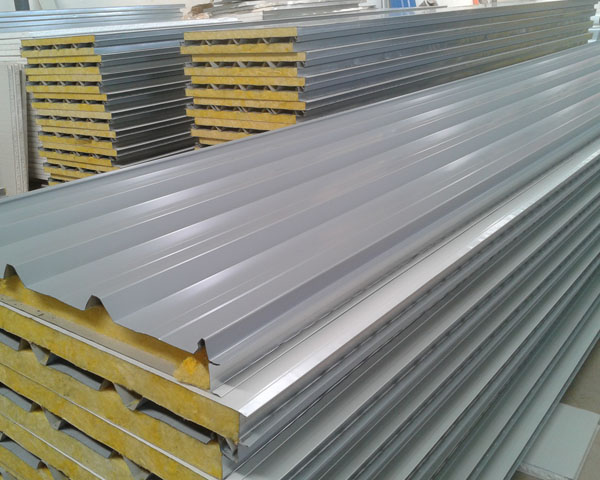

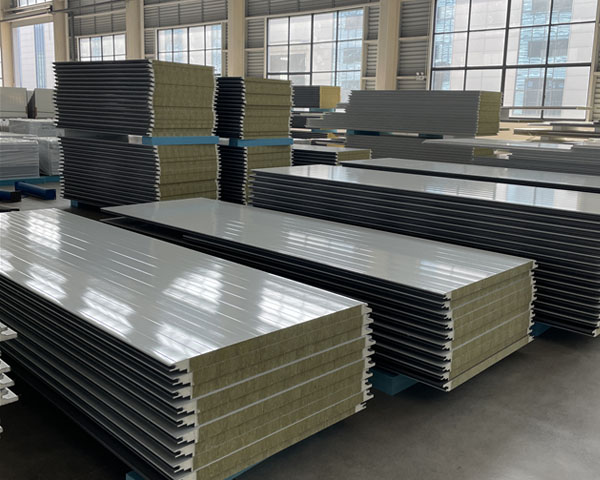

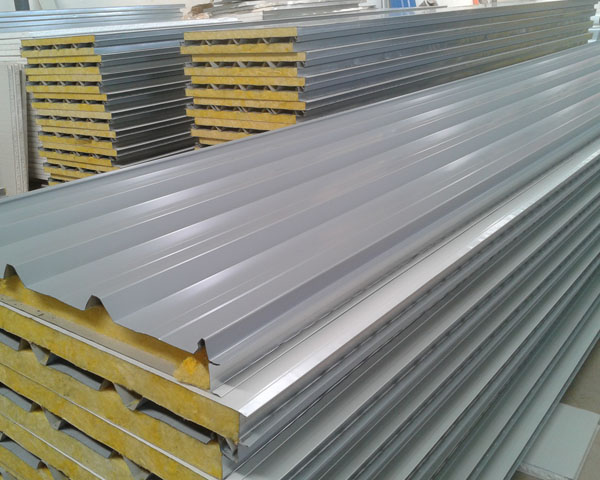

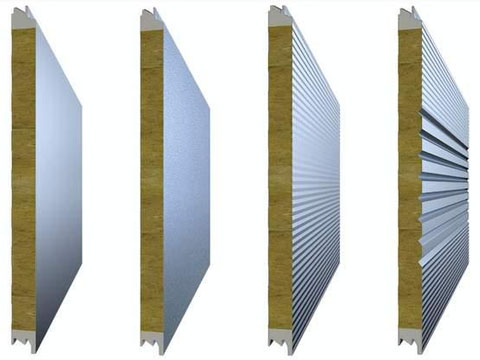

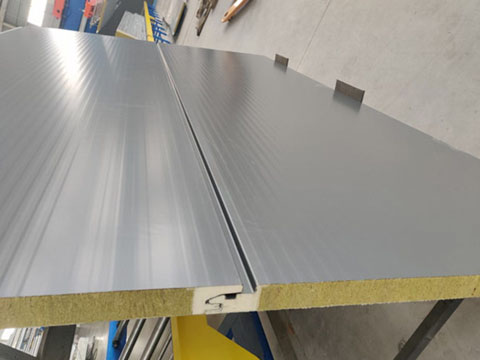

Metal sandwich panels are also called “sandwich panels”. The upper and lower layers are metal sheets, and the middle is a fireproof core material. They are made into composite panels by high temperature and pressure curing. They have functions such as heat insulation, heat preservation, fire prevention, and sound insulation.

We provide you with metal sandwich panels of various sizes, colors, and patterns. The products have the characteristics of long service life, strong decorativeness, convenient installation, fire prevention, and heat insulation.

Metal Sandwich Panel Specifications

| Product Name | Metal Sandwich Panel |

| Total thickness | 50 – 250mm |

| Metal panel thickness | 0.4 – 1.2mm |

| Width | 900mm, 950mm, 1000mm, 1150mm, 1200mm |

| Length | 1 – 12m or cut as required |

| Panel material | Color coated steel, galvanized steel, galvalume steel, aluminum alloy, etc. |

| Core material | EPS, PU, rock wool, glass wool, etc. |

| Fire rating | A、B1、B2 |

| Colors | According to RAL color card or customized |

| Pattern | Wood grain, stone grain, brick grain, camouflage grain, floral pattern or customized |

| MOQ | 5 tons |

| Packaging | Seaworthy packaging or as per customer requirements |

Metal Sandwich Panel Performance Data

| Performance | Sandwich panel type | Technical indicators |

| Flexural bearing capacity | Rock wool/slag wool sandwich panel | When deflection ≤L/250, ≥0.5kN/m² |

| Rigid polyurethane sandwich panel | When deflection ≤L/200, ≥0.5kN/m² | |

| Bond strength | Rock wool/slag wool sandwich panel | ≥0.06MPa |

| Rigid polyurethane sandwich panel | ≥0.09MPa | |

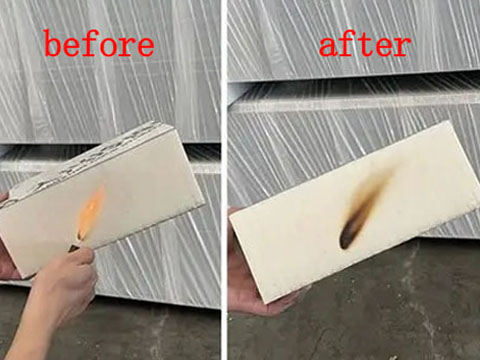

| Fire rating | Grade A (rock wool/glass wool) | Non-flammable, no open flame spread |

| Grade B1 (phenolic foam) | Difficult to burn, slow spread | |

| Grade B2 (polystyrene) | Flammable, flame retardant treatment required | |

| Fire resistance limit | Rock wool sandwich panel (≥80mm) | ≥60 minutes |

| Rock wool sandwich panel (120mm) | ≥90 minutes | |

| Polyurethane sandwich panel | Usually <60 minutes (fire retardant coating required) | |

| Polystyrene sandwich panel | <30 minutes |

Metal Sandwich Panels Advantages

- Lightweight and high strength: The weight of metal panels and core materials is relatively light, especially aluminum, which is lighter. At the same time, it is also strong in bending and compression resistance.

- Strong thermal insulation performance: The core material has a low thermal conductivity, which can significantly reduce energy consumption and achieve energy-saving effects.

- Good fire resistance: Different core materials have different fire resistance levels. We use the lowest B2 fireproof level, and the surface is coated with flame retardant. A1-B2 can meet the needs of different projects.

- Strong corrosion resistance: The metal panels are all made of highly corrosion-resistant metal materials. They are not easily corroded in humid, acidic and alkaline environments and have a long service life.

- Convenient installation: The metal sandwich panels are prefabricated and processed in the factory, which can be assembled quickly. The construction is simple and efficient, reducing construction costs.

Metal Sandwich Panels Applications

Metal sandwich panels are mainly used for roofs, walls, partitions, decorative panels, etc. The main application scenarios include:

- Construction field: industrial plants, warehouses, cold storage, gymnasiums, exhibition halls, light steel villas, mobile homes, etc.

- Public facilities: hospitals, schools, high-speed rail stations, airports, stations, etc.

- Transportation field: ship bulkheads, high-speed rail carriages, aircraft cabin panels (need to be lightweight).

- Industrial field: cleanroom: dust-free workshop, laboratory, etc.

- Temporary buildings: expandable container houses, mobile board houses, exhibition halls, temporary residences after disasters, disaster relief tents, etc.

- Adopt advanced production equipment and use high-quality metal sheets and core materials to ensure the product’s thermal insulation, fire resistance, corrosion resistance and other properties.

- It has a complete product line, including galvanized, aluminum-galvanized, color-coated steel and other metal sheet production lines, hundreds of press-type equipment, metal composite sheet production lines, and its own factory, with more discounted prices.

- Our ISO 9001 certified enterprises are enterprises that value integrity, quality and integrity suppliers certified by authoritative institutions.

As a professional metal sandwich panel supplier in China, Wanzhi Steel, with more than 17 years of production experience and 14 years of export experience, has developed perfect solutions for many customers. It has successfully served more than 120 countries and is well received by customers. If you have any questions about metal sandwich panels, please feel free to contact us.