Galvanized C Purlins

Introduction

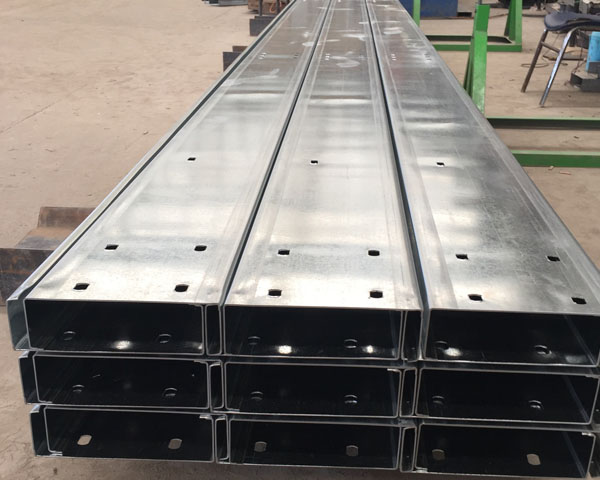

Galvanized C purlin is a common C-section steel building material, which is pressed from galvanized steel strips. Its cross-sectional shape is similar to the English letter “C”.

Galvanized C purlin is widely used in scenarios that require long-term corrosion resistance, rapid construction or high load-bearing requirements, covering multiple fields such as industry, agriculture, civil construction and equipment support, due to its anti-corrosion, light weight and easy installation.

Galvanized C Purlins Specification

| Product Name | Galvanized C Purlins |

| Thickness | 1.5-3.0mm |

| Height | 80-250mm |

| Width | 50mm/60mm/70mm/80mm |

| Flange width | 15mm/20mm |

| Length | 1-12m or as per your requirement |

| Material | Q195, Q235, Q345, Q355, ST37, ST52, SS400, etc. |

| Processing services | Cutting, punching, painting, etc. |

| MOQ | 10 tons |

| Packaging | Seaworthy packaging or as per customer requirements |

Galvanized C Purlins Weight

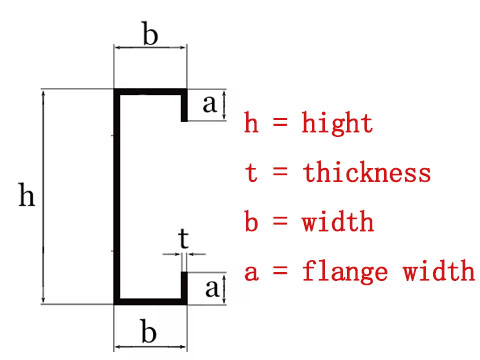

Calculation formula

Weight (kg) ≈ [ (h+b×2+a×2)×t – t²×4 ] × 7.85 ÷ 1000

Note: h, b, a, t are all in mm.

Theoretical weight table

| Size | Thickness (mm) | Theoretical weight (kg/m) | Weight for 6m length (kg) |

| 100×50×20×1.5 | 1.5 | 2.41 | 14.46 |

| 100×50×20×1.8 | 1.8 | 2.87 | 17.22 |

| 120×60×20×2.0 | 2 | 3.84 | 23.04 |

| 150×60×20×2.2 | 2.2 | 4.63 | 27.78 |

| 180×70×20×2.5 | 2.5 | 6.28 | 37.68 |

| 200×70×20×2.5 | 2.5 | 6.72 | 40.32 |

Galvanized C Purlins Product Advantages

Strong anti-corrosion ability

The surface adopts hot-dip galvanizing process, which has strong corrosion resistance and is suitable for harsh environments such as humidity and high corrosion.

Lightweight and high-strength

Light weight, reducing structural load, and at the same time has high bending strength (cold bending processing), strong bearing capacity.

Excellent cross-sectional performance

C-shaped cross-sectional design, excellent bending performance in the vertical direction, effectively bearing roof/wall loads, and ensuring structural stability.

Easy installation

Can be customized by cutting, punching, etc., and fixed on site by bolts, purlins or welding, with a short construction period and no need for large equipment.

Wide applicability

The choice of different coating thicknesses meets the anti-corrosion requirements of different projects; the choice of different materials (such as Q195/Q235/Q345, etc.) meets the strength requirements of different projects.

Galvanized C Purlins Applications

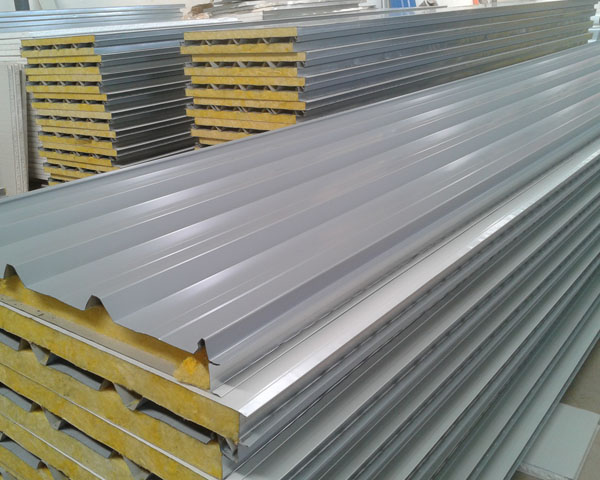

- Construction: wall girt & roof purlin support for steel structure factories, warehouses, gymnasiums and stations, etc., used with color steel plates or sandwich panels.

- Agricultural buildings: frames for greenhouses and breeding sheds, structural support for agricultural product storage warehouses, etc.

- Temporary buildings: structural purlin for folding container houses, modular container houses, expandable container houses, etc.

- Other applications: photovoltaic brackets, indoor and outdoor decoration racks, display racks, etc.; skeleton structures for supermarkets, exhibition halls, and canopies.

Galvanized C purlins price

| Zinc Coating (g/m²) | Specifications and Models | Thickness (mm) | Price per 6 meters (USD) | Price per ton (USD/ton) |

| Z120 | C75×40 | 1.8 | $12.8 – $15.2 | $510 – $580 |

| Z275 | C75×40 | 1.8 | $14.0 – $16.5 | $560 – $630 |

| Z120 | C100×50 | 2.0 | $16.5 – $19.5 | $580 – $670 |

| Z275 | C100×50 | 2.0 | $18.0 – $21.5 | $630 – $720 |

| Z120 | C120×60 | 2.2 | $22.0 – $26.0 | $680 – $770 |

| Z275 | C150×65 | 2.5 | $28.5 – $33.5 | $750 – $850 |

| Z120 | C180×70 | 2.75 | $35.0 – $41.0 | $820 – $930 |

| Z275 | C200×70 | 3.0 | $42.0 – $49.0 | $900 – $1,020 |

Note: The above prices are FOB China port benchmark prices, based on Q235B steel, standard bundled packaging. Using Q345B high-strength steel will incur an additional charge of 18-25%.

Purchasing Tips

- Zinc Coating Selection: Z120 for dry environments; Z180 or higher is recommended for coastal, high-humidity, or industrial areas.

- Thickness and Strength: For every 0.2mm increase in thickness, load-bearing capacity increases by approximately 15%, but cost increases by 8-10%. Select the appropriate coating based on structural calculations to avoid over-design.

- Minimum Order Quantity and Delivery Time: The best unit price is available for standard specifications starting at 10 tons, with a production cycle of 10-18 days.

Why Choose Us

- Strictly select high-quality raw materials, multiple advanced processing equipment, the product cutting surface is flat, smooth and burr-free, and the appearance quality is high.

- The product has high strength, strong corrosion resistance, large bearing capacity, long service life, strict factory quality inspection, reliable quality and stable performance.

- Complete specifications and sufficient inventory can quickly match the C purlins and supporting products you need according to your needs, and support customized specifications.

Wanzhi Steel is an ISO 9001 and ISO 14001 certified manufacturer with 3 galvanized steel production lines, and has longitudinal shearing, cutting, profiling, punching and other equipment, which can provide a rich variety of galvanized steel products. With many years of production and export experience, we can provide you with one-stop procurement services. For more details, please contact us.

Related Products

PU Sandwich Panel

PU Sandwich Panel Introduction PU sandwich panels are also polyurethane sandwich panels, with core material…

Metal Carved Board

Metal Carved Board Introduction Wanzhi Steel’s metal carved board is made of color coated steel…

Metal Profile Sheet

Metal Profile Sheet Introduction Metal profile sheets are made of metal sheets through cold processing…

Roof Sandwich Panels

Roof Sandwich Panels Introduction Roof sandwich panels, also known as sandwich roof panels, are a…

Metal Sandwich Panel

Metal Sandwich Panel Introduction Metal sandwich panels are also called “sandwich panels”. The upper and…