On October 18, 2025, Wanzhi Steel successfully delivered 20 professional medical emergency container houses to the Papua New Guinea government’s health department. These homes provide a standardized, rapidly deployable mobile medical space solution for responding to local tropical infectious diseases such as malaria and dengue fever, as well as public health emergencies.

Project Background

Papua New Guinea has 80% of its population living in rural and island areas, which lack basic medical facilities, putting it under considerable pressure to prevent and control diseases during peak seasons. Furthermore, its tropical rainforest climate and poor transportation in rural and mountainous areas pose a significant challenge to the transport of building materials.

Client Background

The client, the procurement manager of the Papua New Guinea Ministry of Health, urgently needed to procure prefabricated emergency housing that met hygiene standards for use as isolation and treatment spaces. He found us through our Jamaican client. Our prefabricated container houses, with their “ready-to-use, sturdy and wind-resistant, mosquito-proof and moisture-proof” characteristics, became his preferred solution.

Project Challenges

- Tight deadline: The client requires production to be completed within 28 days.

- Harsh operating environment: Tropical climate with high temperature and humidity, frequent typhoons, requiring high building durability.

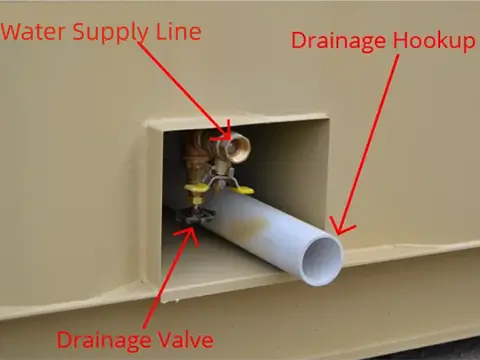

- Rapid deployment: The client requires the goods to be operational within 24 hours of arrival on site.

Execution Order Details

• Type: Packaging container houses

• Quantity: 20 sets.

• Functional modules: Treatment room, isolation ward, medical staff on-call room, medicine storage room.

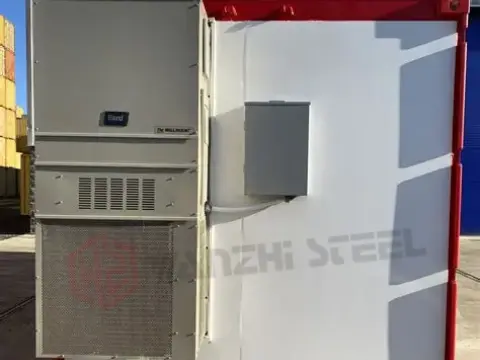

• Core configuration: Mosquito netting, rainwater harvesting system, solar power interface, antibacterial walls.

• Loading method: 12 20-foot containers, 8 40-foot containers.

• Delivery time: 28 days (from production to port loading).

Targeted design

1. Climate-Friendly Structural Design

The ground has a 300mm raised layer with a moisture-proof coating to prevent water accumulation. The structure uses a fully hot-dip galvanized frame and thickened metal sandwich wall panels, capable of withstanding a category 12 typhoon.

2. Hygiene and Epidemic Prevention Design

The client requested the installation of UV mosquito killer lamps, mosquito nets on all windows, and antibacterial wall coatings.

3. Electrical Design

The client requested a pre-installed 3kW solar power interface. For energy efficiency, a dual-circuit design (automatic switching between AC and solar power) was implemented.

Quality Control

Our enclosure steel structure uses S355JR typhoon-resistant structural steel, and the metal roof and cleanroom wall panels are covered with 850μm hot-dip galvanized steel + epoxy zinc-rich primer, and are filled with Class A non-combustible rock wool (100mm thick).

Factory Testing

All finished houses undergo rigorous testing before leaving the factory, including sealing, mildew and antibacterial tests, waterproofing, and load testing. The houses can withstand a negative pressure of 1500Pa, with the roof and walls able to withstand a load of 250kg/m², and the ground surface bearing a concentrated load of 500kg/m². This ensures stability during periods of continuous rainfall and typhoon seasons.

Technical Parameters Summary

- Structural lifespan: 25 years for the main structure, extendable to 35 years with maintenance.

- Applicable temperature range: -20℃ to +50℃.

- Seismic resistance: Meets Papua New Guinea building codes for seismic fortification intensity 8.

- Sanitation standards: Complies with WHO guidelines for the construction of temporary medical facilities.

Delivery And Installation Site

- The entire process took 28 days, utilizing a full container load (FCL) shipment plan consisting of 12 20-foot containers and 8 40-foot containers.

- Customer feedback indicated that upon receiving the goods, a single container was installed within 4 hours using only one crane, modular connections were completed within 8 hours, and water and electricity were connected within 24 hours, allowing the equipment to be put into use the following day.

Why Choose a Containerized Medical Solution?

- There is a need for rapidly deployable medical units on construction sites, in earthquake-prone areas, in remote project sites, or in temporary resettlement areas.

- Containerized medical solutions can be installed more than 90% faster than traditional buildings. They not only respond to emergencies but are also not limited by terrain. Furthermore, 85% of the materials can be reused, minimizing overall operating costs.

Our Core Competencies

- Modular Professional Design: We offer 12 functional modules, including medical, educational, and office spaces, which can be purchased in combination.

- International Project Experience: Completed over 1000 projects in Pacific island nations, Southeast Asia, Africa, South America, and Central Asia.

- Flexible Customization: Offers flexible customization in terms of area, interior layout, decoration standards, and equipment configuration.

If you are interested in packable container houses, welcome to contact us.