Galvanized Steel Coil

Introduction

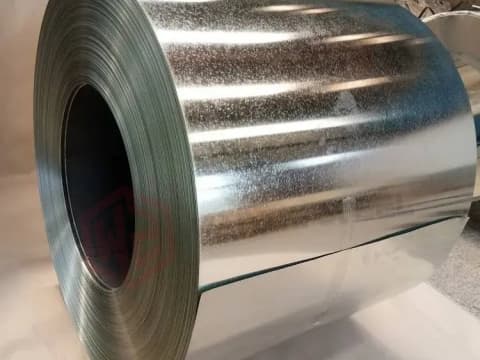

Galvanized steel coils are coiled steel products made from cold-rolled or hot-rolled steel as the base material, with a zinc layer formed on the steel surface through a continuous hot-dip galvanizing or electro-galvanizing process. The zinc layer enhances corrosion resistance and effectively extends the service life of the steel, making it a fundamental anti-corrosion material in construction, home appliances, transportation, and other fields. Commonly used designations include Z120, Z2275, and G90, which combine letters and numbers to indicate the zinc layer content.

Wanzhi Steel offers galvanized steel coils of various base material grades, accepting slitting, leveling, custom packaging, and specifications for thickness, width, and zinc layer. We also provide processing services for galvanized sheets, galvanized steel strips, galvanized purlins, and Gi perforated plates.

Specification

| Item | Galvanized steel coil |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Material | SGCC,SGCH,G550,DX51D, DX52D, DX53D, DX54D |

| Delivery Time | 8-14 days |

| Technology | Hot Rolled/Cold Rolled |

| Zinc Coating | 30-275g/m2 |

| Thickness | 0.12mm-6mm |

| Width | ≤ 1500mm |

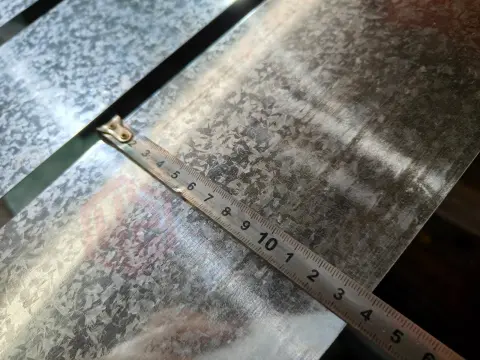

| Surface structure | Big spangle, small spangle, regular spangle, zero spangle |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

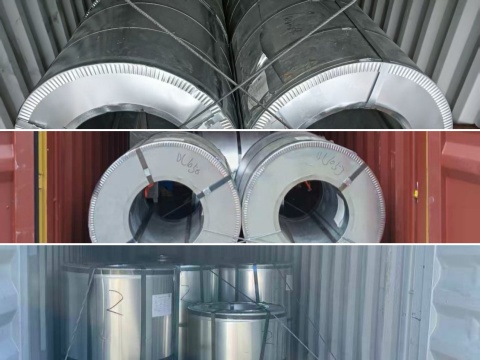

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Production Video

Core Advantages of GI Steel Coil

- Strong corrosion and rust resistance: The galvanized layer isolates the steel coil from air and moisture, extending its lifespan.

- High process adaptability: It can withstand various processing methods such as bending, stamping, welding, and shearing, and the coating is not easily peeled off. It is especially suitable for wall panels, frames, and vehicle bodies.

- High cost-effectiveness: Low cost, mature production process, and low maintenance and replacement costs result in a significant overall cost advantage. A cost-effective alternative to high-priced anti-corrosion metals.

- Diverse surface treatments: It can be layered with passivation, oiling, fingerprint-resistant coatings, and color coatings. For example, color-coated galvanized steel coils can be directly used as building exterior wall panels, and fingerprint-resistant treatments are suitable for appliance casings.

- Wide strength range: Wanzhi Steel offers a full range of grades from low-strength, high-formability to high-strength structural grades, with stable performance within a temperature range from -40℃ to 200℃.

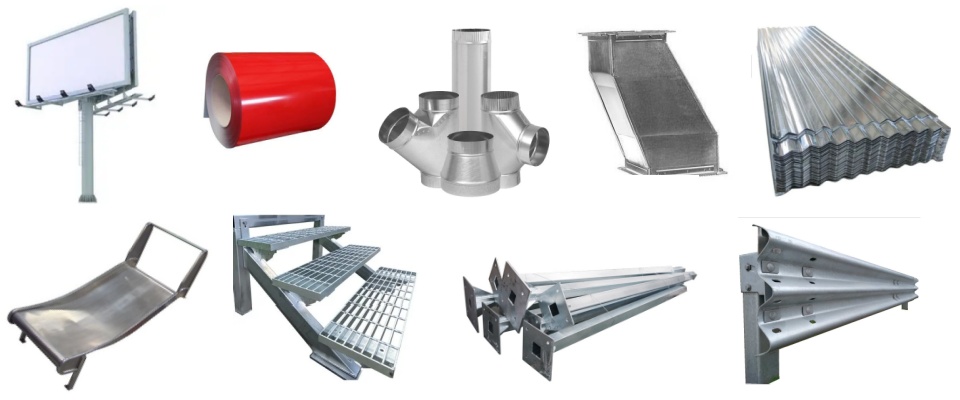

Application

- Construction: Steel structure factory roofs/walls, prefabricated house frames, curtain wall support components;

- Home appliances: Refrigerator/washing machine shells, such as our VCM/PET/PETG/EVA appliance panels, air conditioner outdoor unit brackets;

- Transportation: Automobile chassis parts, container bodies, billboard substrates, highway guardrails;

- Industry: Ventilation ducts, chemical equipment shells, livestock fences.

Industry Standards & Common Zinc Coatings

Chinese Standard (GB/T 2518)

The quality of the zinc coating is classified into grades such as Z80 (80g/㎡), Z100 (100g/㎡), Z120 (120g/㎡), Z150 (150g/㎡), Z200 (200g/㎡), and Z275 (275g/㎡).

American Standard (ASTM A653)

Corresponding to G60 (60g/㎡), G90 (90g/㎡), G115 (115g/㎡), G140 (140g/㎡), and G210 (210g/㎡).

EU Standard (EN 10346)

In line with China’s Z-series standards, Z275 (corresponding to G90) is commonly used as the benchmark for high corrosion resistance scenarios.

Note: The zinc layer weight is the total weight of both sides. For example, Z275 indicates that the total weight of the zinc layer on both sides is 275g/㎡, approximately 137.5g/㎡ on one side, and the thickness is approximately 19.6μm (the density of zinc is 7.14g/cm³).

Commonly Used Substrate Grades & Properties

The base material for galvanized steel coils is divided into hot-rolled steel (HC) and cold-rolled steel (CR), with different grades corresponding to different processing properties and strength levels:

| Substrate Type | Typical brands (China) | Yield strength (MPa) | Elongation (%) |

| Cold-rolled steel | DC51D+Z | 140-300 | ≥22 |

| Cold-rolled steel | DC53D+Z | 140-220 | ≥30 |

| Cold-rolled steel | DC56D+Z | 120-180 | ≥39 |

| Hot-rolled steel | S220GD+Z | 220 | ≥20 |

| Hot-rolled steel | S350GD+Z | 350 | ≥16 |

Character Definition

- “D” represents stamping, and “Z” represents hot-dip pure zinc coating.

- “S” represents structural use, “GD” represents cold forming compatibility, and “220 or 550” represents yield strength.

- “H” represents hard, suitable for high-hardness applications.

These designations are cross-standard (e.g., China DX51D+Z = Japan SGCC = Europe DX51D+Z), serving as a “common language” for industry procurement and design.

Grade Cross-Standard Correspondence Table

| GB/T Standard | JIS Standard | EN Standard | ASTM Standard | |

| Commercial use | DX51D+Z(CR) | SGCC | DX51D+Z | ASTM A653 CS Type B |

| Deep drawing | DC53D+Z | SGCD2 | DX53D+Z | ASTM A653 DS Type B |

| Ultra-deep drawing | DC56D+Z | SGCD3 | DX56D+Z | ASTM A653 EDDS |

| Structural/load-bearing use | S220GD+Z | SG340 | S220GD+Z | ASTM A653 SS Grade 33 |

| Hard material use | S550GD+Z | SG570 | S550GD+Z | ASTM A653 HSLA Grade 80 |

Recommended Selection for Different Environments

Arid Desert Environment

- Corrosion Grade: C1 (Low Corrosion)

- Recommended Zinc Coating: Z80-Z120 (80-120g/㎡)

- Reason: In low-humidity, low-salinity environments, a thin zinc coating is sufficient for over 10 years of corrosion protection.

- Countries: Iraq, Iran, Saudi Arabia, Egypt

Temperate Plains Environment

- Corrosion rating: C2 (low to medium corrosion)

- Recommended zinc coating: Z120-Z150 (120-150 g/m²)

- Reason: Suitable for moderate humidity, used for exterior walls and ordinary steel structures, with a lifespan of up to 15 years.

- Countries: Poland, Belarus, Czech Republic

Tropical Rainforest Environment

- Corrosion rating: C3 (Medium corrosion)

- Recommended zinc coating: Z200 (200g/㎡)

- Reason: In high humidity environments, a thick zinc coating can resist moisture corrosion, extending the lifespan of the roller-coated paint layer to 20 years.

- Countries: Peru, Indonesia, Brazil, Colombia

High-altitude and Cold Regions

- Corrosion rating: C2-C3 (low to medium corrosion)

- Recommended zinc coating: Z150-Z200 (150-200g/㎡)

- Logic: Humidity fluctuates greatly in low-temperature environments; the zinc coating needs to balance low-temperature toughness and corrosion resistance to avoid brittleness.

- Countries: Russia, Mongolia, Kazakhstan, Kyrgyzstan

Coastal/Marine Environment

- Corrosion rating: C4 (High corrosion)

- Recommended zinc coating: Z275 (275g/㎡)

- Logic: High salt spray, high humidity; Z275 combined with heavy-duty anti-corrosion coating can meet a service life of over 25 years.

- Countries: India, Philippines, South Africa, Chile

Process Types of Galvanized Coils

Electro-Galvanized Steel Coil

A zinc layer is formed through an electroplating process. The zinc layer is thin (5-30g/㎡) but has a smooth surface, making it suitable for indoor low-corrosion environments and small parts with high appearance requirements.

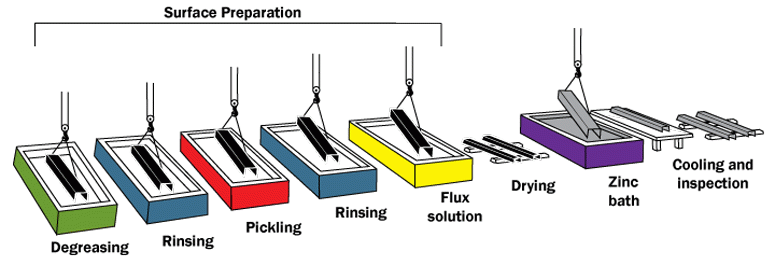

Hot-dip Galvanized Steel Coil

A zinc layer is formed by immersing steel in molten zinc at 450℃. Its core advantages are uniform zinc layer thickness, strong adhesion, and long corrosion resistance, making it suitable for outdoor high-corrosion environments and heavy components.

Surface Treatment for Extended Lifespan

- Passivation Treatment: Forms a passivation film on the zinc layer surface, enhancing resistance to white rust.

- Oiling Treatment: Sprays rust-preventive oil onto the surface, providing short-term rust protection and facilitating storage and transportation.

- Fingerprint Resistant Treatment: Coats with a transparent organic film to prevent fingerprint residue.

- Color Coating Treatment: Film coating/roller coating with four types of organic coatings: PVDF/PE/HDP/SMP, enhancing weather resistance.

- Zinc Layer Alloying Treatment: Grade suffix + ZF, no zinc spangle, high hardness, and good wear resistance.

- Phosphating + Painting Composite Treatment: Passivation followed by spraying of primer + topcoat. 3-5 times improvement in rust resistance.

Selection & Procurement Recommendations

- Matching the Environment: Determine the corrosion level of the application environment, then select the corresponding zinc coating thickness to avoid over- or under-matching.

- Base Material and Processing Requirements: For deep-drawn parts, select low-yield-strength grades such as DC53D+Z; for load-bearing components, select high-strength grades such as S350GD+Z.

- Focus on Additional Services: Prioritize suppliers that can provide slitting, leveling, and customized packaging to reduce subsequent processing costs.

Price of HDG Coil

| Material | Thickness | Zinc layer | FOB Qingdao Port (USD/ton) | FOB Tianjin Port (USD/ton)) |

| DX51D+Z | 0.5mm | Z80 | 610 – 630 | 605 – 625 |

| DX51D+Z | 0.5mm | Z120 | 630 – 650 | 625 – 645 |

| DX51D+Z | 0.5mm | Z275 | 680 – 700 | 675 – 695 |

| DX51D+Z | 1.0mm | Z80 | 530 – 550 | 525 – 545 |

| DX51D+Z | 1.0mm | Z120 | 550 – 570 | 545 – 565 |

| DX51D+Z | 1.0mm | Z275 | 590 – 610 | 585 – 605 |

| DX51D+Z | 1.5mm | Z80 | 510 – 530 | 505 – 525 |

| DX51D+Z | 1.5mm | Z120 | 530 – 550 | 525 – 545 |

| DX51D+Z | 1.5mm | Z275 | 570 – 590 | 565 – 585 |

| DX51D+Z | 2.0mm | Z80 | 500 – 520 | 495 – 515 |

| DX51D+Z | 2.0mm | Z120 | 520 – 540 | 515 – 535 |

| DX51D+Z | 2.0mm | Z275 | 560 – 580 | 555 – 575 |

| SGCC | 0.5mm | Z80 | 615 – 635 | 610 – 630 |

| SGCC | 0.5mm | Z120 | 635 – 655 | 630 – 650 |

| SGCC | 0.5mm | Z275 | 685 – 705 | 680 – 700 |

| SGCC | 1.0mm | Z80 | 535 – 555 | 530 – 550 |

| SGCC | 1.0mm | Z120 | 555 – 575 | 550 – 570 |

| SGCC | 1.0mm | Z275 | 595 – 615 | 590 – 610 |

| SGCC | 1.5mm | Z80 | 515 – 535 | 510 – 530 |

| SGCC | 1.5mm | Z120 | 535 – 555 | 530 – 550 |

| SGCC | 1.5mm | Z275 | 575 – 595 | 570 – 590 |

Success Cases

FAQs

China Galvanized Coil Wholesale Manufacturer

Galvanized steel coils have become the core choice for industrial corrosion protection materials due to their “high cost-effectiveness and strong adaptability.” By matching the process, zinc layer thickness, and application, an optimal balance between performance and cost can be achieved.

Galvanized Steel Coil Factory-Wanzhi Steel

As a professional supplier with an annual production capacity of 400,000 tons, we can provide customized specifications and supporting processing services, covering the application needs of more than 120 countries worldwide.