Galvanized Z Purlins

Introduction

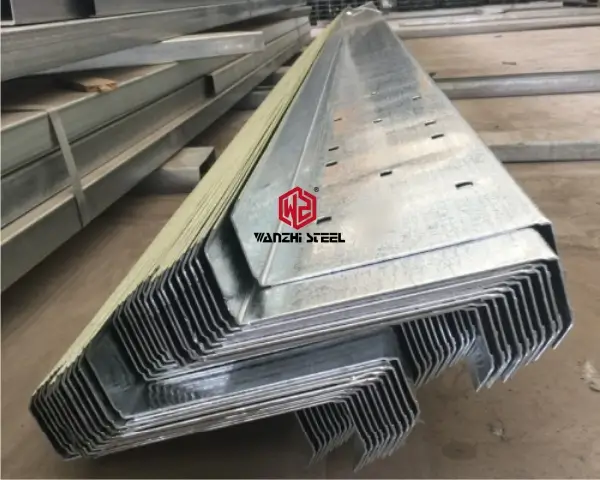

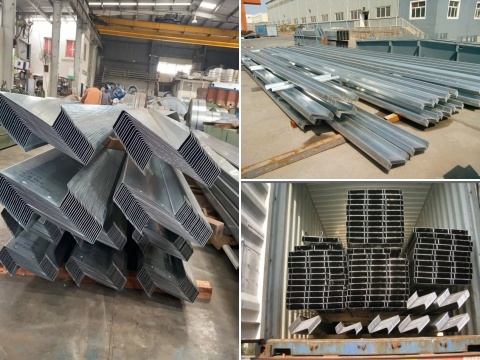

Galvanized Z Purlins (also called zed purlins or z-section purlins) are cold-bent from galvanized steel strips and have a Z-shaped cross-section. Our Z purlins are made of high-quality carbon steel (Q235/Q355) and coated with a hot-dip galvanized layer,which has the benifits of corrosion resistance, lightweight and high strength.

Wanzhi Steel‘s GI Z Purlins are particularly suitable for roof and wall support systems. The “Z” shape provides excellent load-bearing capacity and saves installation space. The zinc coating, thickness, and length can all be customized.

Specification

| Item | Galvanized Z Purlins |

| Place of Origin | Shandong, China |

| Standard | AISI, ASTM, BS, DIN, JIS, GB, EN |

| Material | Q235/Q235B/Q345/Q345B/SS400 |

| Delivery Time | 16-28 days |

| Surface treatment | Hot-dip galvanizing |

| Zinc coating | 30-275g/m2 |

| Thickness | 1.2-3.0mm |

| Length | 1-12m |

| Sample | Free Available |

| Payment term | TT 30% Advance + 70% Balance |

| Price Item | FOB, CIF, EXW, CFR, etc |

| Packing | Standard export packaging |

| Certification | ISO 9001, SGS, ABS, BV |

| MOQ | 5 tons |

Galvanized Z Purlins

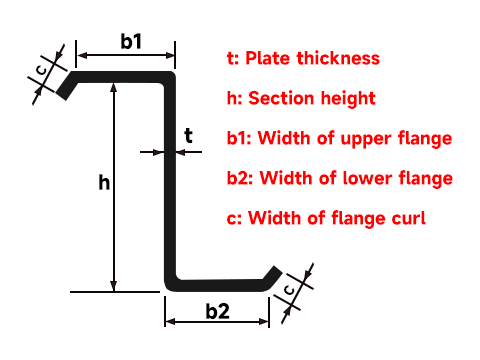

Weight Calculation Formula

Weight (kg/m)≈[(b1+b2+h+2c)×t−t²×4]×7.85÷1000

Note: h, b1, b2,c, t are all in mm.

Size Representation

- h×b×t: Upper and lower flanges of the same width (no rolled edges)

- h×(b1×b2)×t: Upper and lower flanges of different widths (no rolled edges)

- h×b×c×t: Upper and lower flanges of the same width (with rolled edges)

- h×(b1×b2)×c×t: Upper and lower flanges of different widths (with rolled edges)

Material Properties

| Item | Q235B | Q345B | Q355B |

| Chemical composition (%) | |||

| C ≤ | 0.20 | 0.20 | 0.24 |

| Si ≤ | 0.28 | 0.50 | 0.55 |

| Mn ≤ | 0.7 | 1.6 | 1.6 |

| P ≤ | 0.025 | 0.034 | 0.035 |

| S ≤ | 0.025 | 0.025 | 0.025 |

| Mechanical properties | |||

| Tensile strength (MPa) | 380-450 | 550-600 | 550-630 |

| Yield strength (MPa) | 270-300 | 380-450 | 380-450 |

| Elongation after fracture (%) | 28 | 25 | 21 |

Advantages of Our GI Z Section Purlins

- Superior Corrosion Resistance: The hot-dip galvanized coating provides long-term rust protection with a design life of over 25 years, significantly reducing total lifecycle maintenance costs.

- High Durability and Strength: The Z-section efficiently distributes loads and offers excellent bending resistance. For example, our 120mm high Z-purlins have a maximum allowable load capacity of 3.0 kN/m², easily handling heavy snow and strong winds.

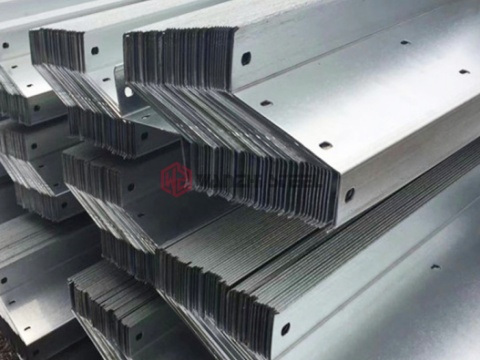

- Flexible Overlapping: Purlin ends can be easily and securely overlapped to form multi-span continuous structures. Pre-drilled holes allow for quick installation, shortening construction time.

- Full Range and Customization: We offer Z-purlins in various standard heights from 80mm to 250mm and support non-standard customization to meet your specific project needs.

Application

- Roofing Systems: Large-span roofs for industrial plants, equipment platforms, and mezzanine load-bearing joists, roof beams.

- Wall Frames: Frames for mobile homes such as modular homes, container homes, and folding homes; supporting structures for temporary buildings.

- Other Applications: Agricultural greenhouses, aquaculture, cleanrooms, outdoor billboard frames, and renovation and reinforcement of old building roofs.

Z & C Purlins

| Characteristics | GI Z Purlin | GI C Purlin |

| Sectional efficiency | High | Average |

| Overlap joint | Easy to implement, continuous beams can be achieved | Difficulties can usually only be overcome by simplified means. |

| Applicable span | Large span | Small and medium span |

| Directionality | Has directional orientation | Basically non-directional |

| Cost-effectiveness | Better overall structural economy | Individual units are cheaper, but the required quantity may be higher. |

| Main applications | Roof purlins (especially for steep slopes) | Wall purlins, small-span roofs, auxiliary structures |

Common Sizes

Our galvanized Z purlins are available in standard sizes (or custom sizes per your foldable house design):

| Z Purlin Height (mm) | Thickness (mm) | Length (m) | Load Capacity (kg/m²) |

| 100 | 1.5 | 6/12 | 200 |

| 120 | 2.0 | 6/12 | 300 |

| 150 | 2.5 | 6/12 | 400 |

| 200 | 3.0 | 6/12 | 500 |

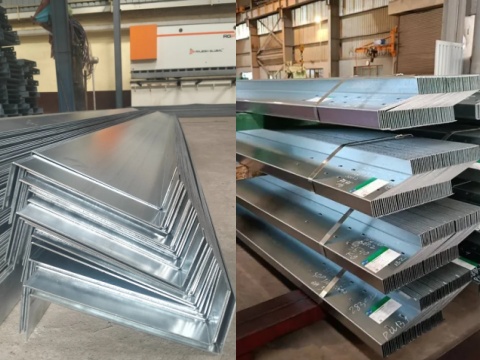

Production Process

Galvanized steel strip coil → Uncoiler → Leveler → Guide device → Multi-pass cold bending roll forming unit (Pass 1: Preliminary flange bending → Pass 2: Forming section height → Pass 3: Folding out the rolled edge → Subsequent passes: Finishing the Z-shaped profile) → Cutting machine to length → Finished product collection (stacking Z-shaped purlins).

FAQ

Why Choose Wanzhi Steel?

- Professional Manufacturing: With over 15 years of experience in manufacturing galvanized Z-shaped purlins, specializing in wall and roof building components.

- Automated Production Lines: 2 fully automated production lines with an annual capacity of 100,000+ tons ensure fast delivery for bulk orders.

- Strict Quality Control: All products have undergone zinc coating thickness, load, and dimensional tests and meet ISO 9001 and SGS certification standards.

- Price Advantage: Free selection advice provided; factory direct sales eliminate middlemen, offering you highly competitive ex-factory prices.

Wanzhi Steel is a leading professional supplier of container houses and construction materials in China. With years of experience in production and export, we offer you more efficient and economical space solutions from a professional perspective. Contact us now for free customization services.